In the field of implant dentistry and regenerative procedures, the interface between biomaterials and bone is crucial. One of the most critical factors influencing successful bone regeneration is surface topography— the microscopic and nanoscale features on the surface of implants and graft materials.

But how exactly does surface topography impact bone healing? Let’s dive into the science behind this concept and explore its growing significance in modern regenerative dentistry.

What Is Surface Topography?

Surface topography refers to the physical texture or architecture of material’s surface. In dental applications, this typically applies to implants, membranes, or bone grafts. These surfaces may be:

– Smooth or polished

– Roughened or textured

– Micro-structured or nano-structured

– Patterned or porous

Each other these topographical features can influence how cells behave on the surface—especially osteoblasts (bone-forming cells) and mesenchymal stem cells.

How Surface Topography Influence Bone Regeneration

- Enhanced Cell Adhesion and Differentiation

A rough or microstructured surface enhances the adhesion of osteoblasts and encourages, their differentiation. This is essential for early osseointegration, especially in dental implants. The physical cues from the surface can activate signaling pathways that push stem cells to become bone cells.

✅ Scientific insight: Nano-rough surface have shown increased expression of osteogenic markers like alkaline phosphatase and osteocalcin. - Improved Osteoconductivity

Topographical features like grooves, pits, or porous surfaces serve as scaffold that guide the growth of new bone. This property, known as osteoconductivity, helps the body regenerate bone along the surface of an implant or graft material.

✅ Clinical relevance: Modern implant designs often mimic trabecular bone patterns to encourage natural bone growth. - Faster Osseointegration

Time is critical when placing implants. Surface-treated implants—especially those with nano-scale roughness— have demonstrated faster and stronger osseointegration compared to smooth implants. This can reduce healing time and improve long-term implant stability.

✅ Technology spotlight: Techniques like sandblasting, acid etching, anodization, and laser texturing are used to modify implant surfaces for this purpose. - Antibacterial Properties

Surface topography can also be engineered to have antibacterial effects, reducing the risk of infection post-surgery. Nanopatterns can disrupt bacterial adhesion without harming surrounding tissues.

✅ Future potential: Research is ongoing into biomimetic surfaces that deter bacteria while promoting bone formation— a win-win for peri-implant health.

Applications in Regenerative Dentistry

Surface topography plays a role in several regenerative dental procedures, including:

- Dental implantology

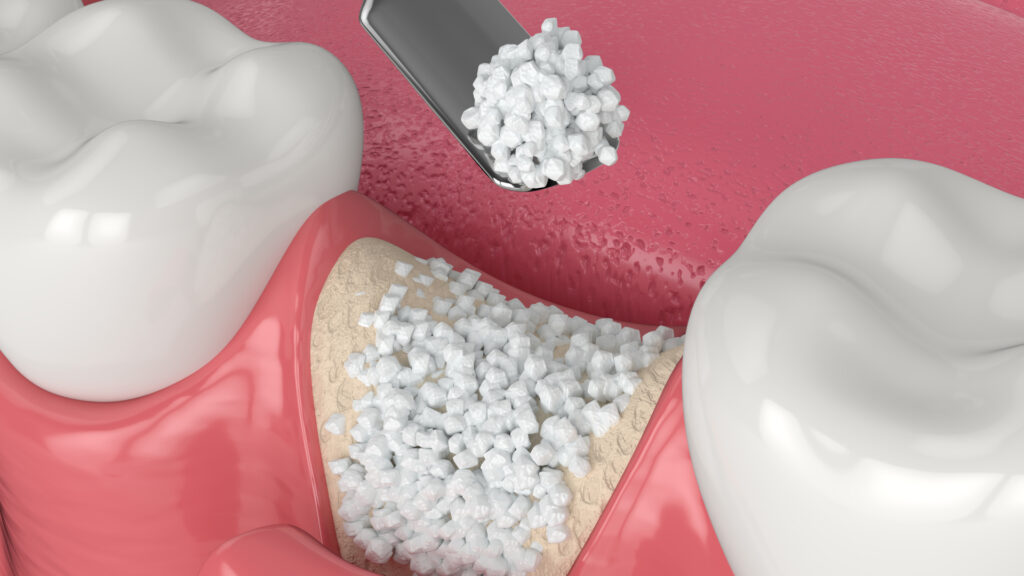

– Textured surfaces enhance implant integration, especially in low-density bone. - Guided Bone Regeneration (GBR)

– Membranes and grafts with patterned surface improve cellular interaction and tissue regeneration. - Bone graft substitutes

– Alloplasts or xenografts with micro- or nano-topographies show superior osteoconductive performance.

Future Directions: Biomimicry and Smart Surfaces

The future of bone regeneration lies in biomimetic designs—creating surfaces that imitate the natural extracellular matrix of bone. New research is also exploring ” smart surfaces ” that can respond to the biological environment, releasing growth factors or changing properties based on cellular signals.

✅ Emerging innovation: 3D-printed implants with customizable topographies tailored to individual patient anatomy and bone quality.

Conclusion: Topography as a Tool for Success

Surface topography is far more than a material feature—it’s a powerful biological signal. In bone regeneration, the right topography can mean the difference between success and failure. As technology advances, dental professionals must understand and leverage these properties to enhance clinical outcomes.

Whether you’re placing implants, conducting bone grafts, or planning GBR procedures, choosing materials with optimized surface topography is key to long term success.